Our Story

An Entrepreneurial Spark

The Legend was Born

Mobile Wash of America found early success and quickly expanded into duct and hood vent cleaning. Chimney cleaning (being a form of a duct) was added at the time. The cleaning business led to expansion of janitorial cleaning which included serving nursing homes. Steve soon had multiple crews serving the middle Georgia area. Business was booming, but the cleaning products they used were difficult to handle.

“We had 55 gallon drums of cleaning chemicals that weighed 500-700 pounds. While off loading a drum of degreaser from a tractor trailer by bouncing the drum off the back of the truck onto a tire, the seam split and I got soaked.”

This was the Eureka moment.

Steve saw an opportunity to do things better. He wondered why a super concentrate could not be made so the same amount of product could be delivered in a five gallon pail. Steve contacted a friend Cory Hammock, a local chemist. The two spent months brainstorming on this concept. The nursing home market needed a product that would get rid of odors from bed pans, soiled bed linen, and Colostomy bag odors. The ‘Cancer smell’ associated with patient rooms was an entire category all unto itself. Many trials testing OdoBan on baby diapers were conducted to test the product. Cory gave Steve the formula to make the first batch and promptly left town. This was before cell phones and answering machines. Steve took the raw materials home and poured them all in his bathtub. After many hours of stirring the materials together, it became apparent the many color variations were not going into solution. Unbeknownst to Steve the raw materials had to be mixed in a specific order. The first raw material had to be added to the second before you added the third, and so on and on. Cory returned after being gone for the weekend and after coaching Steve on the proper technique the first batch of OdoBan was made right here in Warner Robins on American Boulevard.

Freshness For All

After calling on Sam’s Club for several years, they agreed to take a chance on a small company back in 1990. Realizing the potential of OdoBan and knowing you can’t serve two masters, Davison sold his janitorial company and established Clean Control. By 1995, the OdoBan product was carried Nationwide in Sam’s Club which enabled Clean Control to expand with additional products and line extensions. Clean Control has been able to expand and grow to the company it is today because of the willingness of Sam’s/Walmart to take a chance on a small, local manufacturer back in 1991. Only in America! Starting as a small business, the basic philosophy has always been to go one step further.

“We didn’t just make a deodorizer, we developed an odor eliminator and disinfectant that cleans. We didn’t just make something to mop up grease, we developed bacterial solutions that would eliminate grease, which was the basis for our bacterial line,” says Davison.

Back to Back! In May of 2017, Clean Control Corporation was recognized as Partner of the Year in the U.S. EPA Safer Choice Program for advancing the goal of chemical safety and continually driving innovation; FOR THE SECOND YEAR IN A ROW! The U.S. EPA Safer Choice label helps consumers easily find products that are safer for people and the environment.

The OdoBan® brand of products is recognized worldwide as a leading solution for odor elimination and disinfecting. Thus, Clean Control’s customer base has grown to serve various market segments which, today, includes household consumers as well as wholesale, industrial, commercial, and institutional customers around the globe. This market diversity is a tremendous testament to the quality and effectiveness of Clean Control’s product lines.

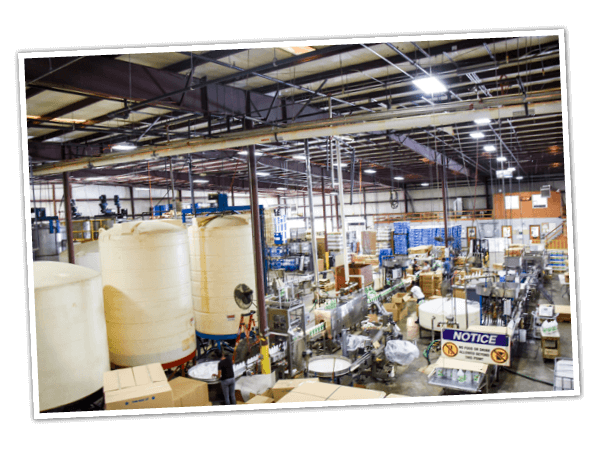

Davison attributes the company’s ongoing growth to his Christian beliefs as well as his passion to provide innovative products for the industry. Clean Control’s capabilities include manufacturing, sales, shipping, distribution/logistics, marketing, promotional packaging, graphics, POS, and display services for all product lines.

In 2013, Clean Control added a 150 kW grid-tied, ground-mounted solar array that produces approximately 80% of its energy usage.

American-Crafted Cleaning Products

We’re serious about freshness. That’s why we make the best, American-made cleaners, disinfectants, and odor eliminators on the market. We produce and package OdoBan in small batches, year-round at our facility in Warner Robins, Georgia. As an independently-owned company, we take great pride in what we make. Every OdoBan product is backed by our 100% Satisfaction Guarantee.

From our hands to your home, we invite you to “Make Life Fresh”, with OdoBan.

Going Green + Environmental Sustainability

Making effective and environmentally sustainable products is the heart of the OdoBan mission.

Here are some ways we’re working towards a better tomorrow:

Solar Energy

In 2011, we installed 150kW grid-tied, ground-mounted solar panel array at our headquarters and manufacturing facility in Warner Robins, GA. These panels offset our electrical usage by an estimated 392,000 kWh annually.

Aquatic Toxicity

We only use surfactants (a cleaning ingredient) that biodegrade readily to non-polluting substances, which helps relieve stress on the environment, especially threats to aquatic life. By avoiding environmentally harmful builders or extreme pH in our formulas, we improve the environmental profile and safety characteristics of our products.

Packaging

Concentrated products use less packaging. Additionally, we’ve phased out PVC packaging and work closely with customers to reduce corrugation without compromising container integrity.

Phosphorous

Although essential for many biological processes; use of phosphorous compounds such as inorganic phosphates results in increased amounts of phosphorus as pollutants in bodies of water resulting in eutrophication. Eutrophication devastates water ecosystems. That’s why you’ll never find inorganic phosphates in our products.

Recycling

We recycle manufacturing materials such as corrugated packaging (cardboard), high-density polyethylene (HDPE) and polyethylene terephthalate (PETE) containers. We also promote recycling in the local middle Georgia community where we live and work.

Nitrogen

Although essential for many biological processes; use of nitrogen compounds such as ammonia and monoethanolamine (MEA) is causing dramatic environmental changes, including surface and groundwater pollution and ocean dead zones. Nitrogen compounds are highly toxic to fish and the discharge from wastewater treatment plants must be closely monitored. OdoBan products lead the industry in the development of floor strippers and concentrated laundry detergents without MEA.